A few days ago, I had made the drawcord warp in four sections, placed the sections on the rod that fits inside the top beam, and began to spread the sections into the raddle. I discovered that although I had done my warp calculations correctly, my thinking of groups in the raddle did not match, so I had to move a couple threads every other section to their proper space in the raddle. This wasn’t a big problem, and I certainly won’t make that mistake again!

Once that was done today, the lease sticks were put in. While checking, I found 4 cords at the cross, scattered across the warp, that had not been caught in the lease sticks. I do not know if this happened at the warping board, or if we missed those cords while inserting the lease sticks. They were put properly in place, and the drawcord warp was beamed this afternoon.

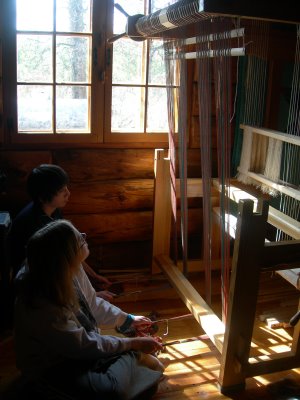

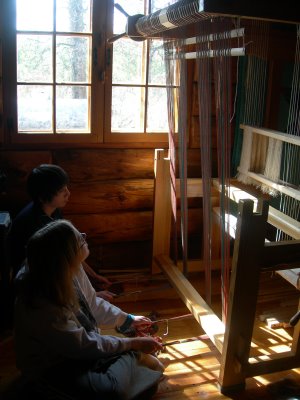

The Swedish method of beaming a drawcord warp includes rough sleying a reed before winding the warp on. I chose not to do that, but to simply do my usual back to front warping method. I did, however, run the warp straight down and under the footboard of the loom as done the Swedish way. Noah and Sarah held the warp sections while I wound the warp on and inserted a few warp sticks. I then cut the ends and tied off, as shown below, to keep the lease sticks in place.

Next, I believe I will be able to suspend the reed directly underneath the lease sticks, pick the threads from the cross, and sley the reed, one cord per dent, 8 cords of teal, leave a dent empty, 8 cords of terra cotta, leave a dent empty, and continue alternating colors across the reed.

Once the sleyed cords are secure, I will remove the raddle, then unwinding enough drawcord warp, move the reed and warp ends back across the loom, over the steel beam, and down, so I can pick threads from the first reed, to sley the second reed. The first reed will then be moved back to the top beam and secured there. After the 20/2 weaving warp is beamed, I will be able to tie the cords to the pattern heddles.

What is all this for? The single unit drawloom is a double harness loom. It has a front ground harness, in this case 10 shafts available, and a pattern harness, which on this loom consists of four rods/shafts on which the pattern heddles hang. The pattern heddles will be set up and hang as if they were a straight twill. Each pattern heddle has a maillon through which 1 to 8 threads are threaded and works as a unit.

The ground shafts will be most likely set up as a 5 shaft satin. A design will be graphed out, and the the cords of the drawcord warp are used to pull up units of threads to create the design.

I will try to do a better job explaining this as I work through the process of setting up this loom. It has been a long time since I’ve done this, and all I have to go on are memories, a few books, most in Swedish, the CW Double Harness Study Group, and a little creative thinking. My ideas may or may not work, but either way, I will learn from them.

I’ve been searching for 20/2 mercerized cotton, on cones, so far without success, so I’ll be continuing that search this evening. While waiting for the 20/2 cotton to arrive for the warp, weaving will continue for spring, summer, and autumn at the galleries and a couple art shows. Towels, runners, rugs, and bags, and more ideas keep coming. All that plus working on my studio and home. Each day is a challenge or an adventure, sometimes both.