Older now, she had gotten very deaf, only hear very loud sharp noises, and recently had developed the canine version of dementia. She still knew us, her family, but wandered around, standing in corners, getting tangled up under looms constantly, either restless or sleeping. She was getting meds for both her bad leg and the dementia. About a month ago, she was let out at night, wandered from the yard and was out overnight, lost in the dark. We found her at 7:30 AM the next morning, caught in some dead lower pine tree branches, unable to get out, not far from our home on the county land next to us.

Northwoods Art Tour, Day 1

Today was my first Art Tour day, lots of fun, great conversations with visitors, and good questions about what I do. One woman, though, said it all,… “This woman has thousands of dollars worth of looms, and we’re all fascinated by the sock machine!” Totally True!

I had about 20+ people here throughout the day, more than I expected, given this is my first year, and sales were better than I hoped they would be, so feeling good about both. A number of pairs of socks sold, along with four towels. Tonight, I’m wishing I had had a lot more socks done to sell, but I wanted so badly to get the drawloom going that I gave that priority.

For myself, a good part of my reason for doing the art tour was to provide an opportunity for people to see the looms, spinning wheels, and sock machine, and ask questions/get answers. Sales of my work are just a happy bonus.

I did get three socks cranked today while demonstrating and talking with people, along with demonstrating weaving and explaining the drawloom. There would have been a fourth sock, but one of the yarns caught, snagged and broke while finishing up the toe, darn!

I have Art on Main coming up on Aug. 9th, Art in the Yard on Sept. 19th, and the fall art tour Oct. 2-4, so sock-cranking will be a high priority in the coming weeks. With the coming cold winter weather coming, there will probably be even more interest in wool socks.

Today, between visitors, I started my first rag rug. The stripe warp has been sitting on the CM loom patiently waiting, so I’m now looking forward to my first rag rugs. The drawloom is nearly ready to go, the reed is half sleyed, though I’m considering waiting and ordering a 15 dent reed on Monday which would be here probably by Thursday.

The lighting isn’t great on this, given this is a dim log home/studio, with an Ott floor lamp for light. These rugs will certainly go faster than some of the weaving I’ve done lately, at least the weaving part, not forgetting there is weft prep, too. I do like the effect of the “ticking” stripe in the sheeting as it is woven in, with thin random green stripes coming to the surface.

So, I’m looking forward to Days 2 & 3 of the Art Tour and meeting more people with an interest in, or curiosity about fibers, looms, and sock machines.

Drawloom Progress Continues

Northwoods Art Tour Begins Tomorrow

The Northwoods Art Tour begins tomorrow and lasts three days, Friday thru Sunday, July 24-26, 9 AM to 5 PM. I am looking forward to visiting with people on the tour and sharing my love of fiber arts, and demo’ing weaving, spinning, and sock cranking.

Time to get a warp tied on, take care of some more cleaning, and pull a few weeds. What do they always say?… when you’ve been putting off cleaning, invite some people over? Well, I did!

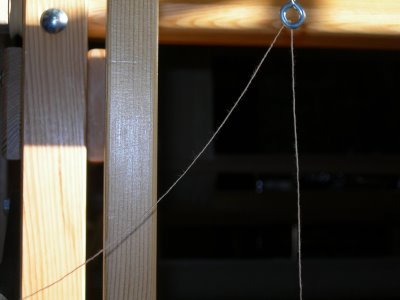

Drawcords Tied to Pattern Heddles

I also cut Texsolv cord in the two lengths needed for the treadles, in this case, 16 cords (8 long and 8 short) and singed the ends to make them easier to pass through holes in the lamms and treadles. Unlike a regular countermarche loom, the drawloom will have only two ties on each treadle, one to raise, one to lower, the other shafts stay in a neutral position.

This evening, I ran into Fiona and son Luke at a store tonight. She had looked at this blog again today and said she now has a whole new appreciation for handwoven textiles, and the preparation needed to make them. They are coming to the studio Friday morning, on the art tour and I am looking forward to their visit.

I was hoping to get more done tonight, but I’m going to get a good night’s rest so I can start early and do a lot more on the drawloom tomorrow. In the morning, we’re putting the center cords back down through the shafts, adding the lamms and treadles, and tieing up the treadles for the 8 shaft satin weave. Then I’ll thread the ground shafts (long-eye heddles). I’m getting a step or two closer every day.

Pattern Heddles are Done!

It is 3 AM, early Monday morning, and I just finished threading the pattern heddles on the drawloom, refusing to go to bed until they were done.

Today, after I get a few hours of sleep, I need to tie the drawcord warp ends to the tops of the pattern heddles, add the lamms and treadles (and Texsolv cords), tie up the treadles, and hopefully thread the ground shafts in an 8 shaft satin, or at least get started. The counterweights also need to be added to the loom. After all that is done, it will be time to tweak things to make sure warp is running where it is supposed to, and get a decent shed. I expect all this will take the better part of two days or more, depending on interruptions.

I have so much weaving and sock cranking to be done, and need balance back in my life, but I can’t seem to stop working on this drawloom.

Threading Pattern Heddles

The chair shown in the photo is how I climb into the back of the loom, not an easy task at the moment, with lease sticks, two warp sticks supporting them, etc. in the way.

Drawloom ~ Beaming the Warp

Details: The warp was 20/2 mercerized cotton, 64 ends per inch, 16″ wide, and 18 yards long for a total of 1,024 threads, and 18,432 yards. The warp was made on a warping mill, and made in 4″ sections of 256 threads each. I warp back to front.

The warp was placed on the back wood rod, each one inch section put in its place in the raddle and held down with rubber bands. Beveled lease sticks were placed into the cross and the ends of the lease sticks tied to each other to prevent one (or both) from ever dropping out and losing the cross. On the CM loom I sometimes use the lease stick holders, but on this particular drawloom there is no upper structure over the long back extension to tie them to. When removing choke ties, for example, and no tension was on the warp, two longer warp sticks from the wider CM loom were used as supports under the lease sticks, then removed when tension was again on the warp and we were ready to continue winding on.

Warping Behind Schedule

I started this warping process with a fine 20/2 cotton thread about three days ago. Things were going well and I made the first of the two warps which will only be about 5″ wide, sett is 36 epi. Two nights ago I decided it will be beamed onto the Glimakra table loom.

Above, is one-fourth of the drawloom warp, counting thread on, and just before adding cross and choke ties. I’m making it in four 4″ sections, 64 epi, and 18 yards in length. The overall width will be 16″ for a total of 1,024 threads, placed on the warping mill one thread at a time. I’ve already decided I’ll be experimenting with making these warps perhaps 4 threads at a time using a fixed warping paddle.

This mill is 3 yards around, so to make the warp in two sections, I would have had to shorten the length of the warp. Since my drawloom has the long extension on it, and I did not want to re-warp and re-thread right away, I decided 18 yards would be good. Trying to squeeze more threads onto the mill would, in my opinion, be risking tangling of threads or worse.

So, why am I not done? I’ve been distracted! A couple weeks ago I’d started to set up an online shop on 1000 Markets, and submitted it for approval on July 4th. Three days later an email arrived requesting I retake photos of the towels in natural light. So I spent two days taking photos of both the towels and socks (might as well do them over, too), somewhere over 100 photos. After deleting most of the pictures and keeping those I thought were okay, I resubmitted for approval again a couple days ago.

Last night, around 10:45 PM, an email arrived saying my shop was Live! Now, I’m busy learning my way around 1000 Markets, reading in the Forums, browsing through Markets to determine where I might fit, and so on. Today I requested being part of two markets, and heard back from one almost immediately. I still need to set that up, and perhaps post a first blog entry there, hopefully tomorrow.

So in-between all this online time, I have been working on my fine warps. Half the drawloom warp is done, and I’ll be back at the warping mill again tomorrow. I’m really looking forward to threading, though I’m thinking when that is done I’ll definitely need new glasses.

It’s cool again tonight, around 50 degrees out, but the Whippoorwill has been singing away since just after dark. He sings me to sleep every night, just under my bedroom window.

.

Fine Warps, in Progress

Here is perhaps the first inch of warp on the warping mill. Time to add my counting thread.

Running the cotton through my fingers, it’s almost like there is nothing there. This is my introduction to finer threads, and this isn’t as fine as some of the linen and silk samples I’ve seen, not to mention a couple samples I’ve seen that have sewing thread for warp and weft.

Here are a few of the colors of 20/2 cotton I have available for weft. I’m really looking forward to this weaving, following the treadling variations given in the book, and then seeing what I can come up with.

Now, back to my warping mill.