Here it is, my first real rag rug completed and on the floor! Looking at it now, I like the warp stripes and colors, as well as the weft colors. It lays quite flat, selvedges are nicely even, and only a tiny bit of “smile.”

It seems to meet the tests of a good rag rug ~~ you can’t put your fingers through anywhere, and when rolled up and stood on the floor it stands. Another “test” I read in the book “Finnish American Rag Rugs” is hold the rolled up rug in your hand, palm up, at shoulder level, the rug should not droop, and happily, it doesn’t.

The rug passed another test here, too, right after taking these photos, I walked over to the computer to download them, turned around, and there was a cat already laying on the rug. No, I’m not ready for a 50 pound Keeshond and five cats to enjoy this rug just yet, so yes, I picked it back up off the floor.

Another view of my first rag rug.

Details: 8/4 cotton rug warp, sett 12 epi. Good tension when weaving, beat hard, change sheds, beat hard again, and I used a temple. Weft strips are sheets purchased at thrift stores, cut into 1 1/2″ strips and the strips were sewn together. When winding the ski shuttles, I wound the weft on folded in half and when placing the weft into the shed, made sure it was still folded.

Hems at each end are cutton rug warp, two threads per shed using a double-bobbin shuttle. I started by weaving an inch or so of string, then 3 1/2″ hem, and reverse at the other end. I cut the rug from the loom, machine sewed each end 3″ from the first “rag” row, rotary cut just outside the machine sewn line, then pin and sew the hem. The finished rug measures 28″ wide, 55″ long.

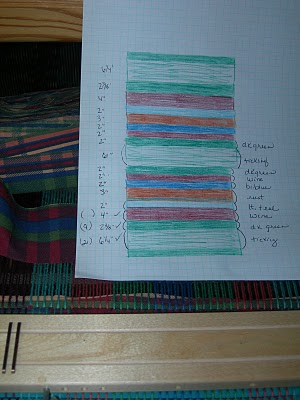

The warp has been tied on again. I’ll use some of the same strips/colors so they are ready to use, but I’ll need another three or four colors so must get those cut into strips and ends sewn which shouldn’t take long. The second rug shouldn’t take as long now that I’ve gotten a bit of experience.