|

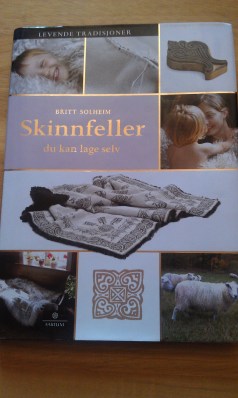

| “Skinnfeller” by Britt Solheim |

I had written awhile back that I would like to weave a Norwegian coverlet, likely a small Christening size to start with, and one that would have sheepskin on the other side. But how to do that? About a year ago I posed that question on ScanWeave, and was told of a book that had been available at Vesterheim Norwegian-American Museum. I contacted them and was told they were out, and trying to get more. In February I received an email and a phone call from them, the book had been reprinted and they had obtained copies, did I still want one? Yes! The book is very pricey, and written in Norwegian, but I wasn’t going to let that stop me.

So “Skinnfeller du kan lage selv” (Leather Traps You Can Make Yourself) by Britt Solheim. The book seems to be about a type of bedcover that is tanned sheepskin that is also sewn with techniques that give flat seams, with designs printed on the tanned hide, not the woven type with sheepskin on the underside. But since it is the sewing part I am interested in learning about, and the pleasant surprise that this type of cover would be a fascinating project, I am still happy with the purchase. To that end, I have just started translating the book (for myself) using Google Translate, a dictionary, and two Facebook Friends in Norway who have offered to help me if translation doesn’t make sense or needs refining.

If you Google “www.skinnfell.no/, then click on Translate Page, the website will come up in English. Then, on the left, click on “Skinnfell blogg” and the blog will come up in English. Enjoy! (Added to the post Friday evening.)

And now while typing this, I just arranged to get another book, same or similar topic, that will be in Swedish. The newest VAV Magasine had an article, “Kalder Sheepskin,” pp. 36-37, and notes about a book “Lammskinn.” I had emailed the address given at the end of the article, twice, but no reply. When I mentioned that to one of the Norwegian FB Friends, she offered to order the book and have it sent to me. So now I am looking forward to seeing that book, also, and then translating it as well. Never a dull moment! I will post more about this book after it arrives.

Meanwhile, I am working on my woven shibori samples, and definitely need to pick up the pace. And, a dye area still needs to be set up. My first deadline, May 1, is coming up fast, when Amy needs photos of the new work so our postcards can be printed and mailed out for our Aug. 10th Art Gypsy art show in Land O’ Lakes, WI.

|

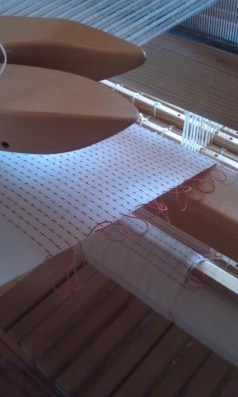

| Woven shibori samples on the loom. |

I hadn’t posted because at this point, these samples are still looking rather boring! These samples are Swedish cottolin, half-bleached, both warp and weft (plain weave). The pattern rows (twill, spaced out) Half-bleached cottolin with seine twine woven into the pattern rows.

|

| Samples off the loom. |

After being removed from the loom, the loops are cut, pulled very tightly from each side, and tied tightly, to prevent dye from penetrating into those areas which is what gives design on the finished pieces. The pattern threads are removed after dyeing. Until they are dyed, they are not too exciting to see, but I am enjoying weaving them!

|

| Sample after gathering. |

Width in the reed is 8″ yet after being gathered (off the loom), it measures 1.5″ wide, and I think I should have pulled the threads even tighter. Glennis Dolce (Shibori Girl and indigo dyer) suggested dampening the piece after some gathering is done, then pulling even tighter again before tying the knots along the side. To test that idea, I made two identical samples, one will be gathered without dampening, one with, then both will be dyed at the same time to find out which method works better, or if there is little or no difference. Thank you, Glennis, for the suggestion! Results will be posted here on the blog along with photos.

Right now, before dyeing, I’m trying to figure out how I can lable each sample as they are each being treadled differently. Handstitch a number on each? Or just use a permanent laundry marker (not terribly attractive). So far, I’ve been keeping simple records of the samples,… the fiber, threading, tie-up, followed by the treadling of each sample. This way if there particular patterns or effects that I like, I’ll be able to duplicate them, at least as much as dyeing will allow.

While finishing up my samples, it’s time to research and decide on what size cotton I need to warp up for scarves, do my calculations, and get a warp or two made, ready to beam as soon as the samples are finished.

|

| Carving for future printing. |

Something I’ve been playing with late in the evening, occasionally, is a bit of carving. I’m using Soft-Kut, and usually the “U” shaped tool. Sometimes a spare “sketch” directly onto the Soft-Kut with a pencil, then carve adding more detail, or else carve freehand, just see where an idea goes. Why? For future printing on fabric!

|

| Drumcarding fibers for felting. |

I needed a change of pace this afternoon, so drumcarded some white roving, adding in bits of royal blue and navy.

|

| Spots of color, ready to felt. |

|

| After felting. |

After finishing this blog post I went down and felted this piece, which early next week will be made up into a couple small items. For now, it is laying across the top of a wood drying rack near the woodrange. It’s very possible I’ll go back down tonight and card up a couple more different colorsways to felt tonight or tomorrow. Sometimes you just need to do something out of your ordinary routine!

|

| Woodsmoke drifting across the lake early one February morning. |

|

| A young pine with its burden of snow. |

Like many other places, we are in the end of winter slump here in the WI Northwoods, tired of snow and cold, and looking forward to the change from white to green, the return of songbirds, sunshine, and warmer temps, knowing full well cloudy days, spring rains, and the “mud” season will come first. However, more snow in the forecast over the next three days or so. Time to return to fibers!