I will be changing other tie-ups (shafts to jacks) over to Texsolv cord, as well as using Texsolv cords from jacks to treadles. In these cases, I prefer the Texsolv for making adjustments over tieing knots in the old way. Sometimes, convenience wins out.

All posts by janicezindel

New Beginnings for 2009

The New Year seemed a good time to begin the new warp, a 10 shaft twill with stripes of bleached and unbleached 22/2 cottolin, sett at 24 epi, 2 epi in a 12 dent reed. This afternoon I tried out a singles slub linen, first with one strand, then with two, both as plain weave and twill. Ideas for borders are going through my head as I weave. In a bit, I’ll begin weaving the first towel or runner on this 15 yard warp.

Also this afternoon, my son Noah made a heddle jig for me, cutting and sanding a board and setting in the nails for the long-eye heddles I need to make for the drawloom. There is a heddle on the jig, though the seine twine is difficult to see here.

Wishing You and Yours…

Studio Days

It was cold and windy in the northwoods today, warming up to a brisk -6 F around 10 AM this morning. A great day to stay in the studio and do more cleaning and organizing. More and more I want clear, uncluttered, organized work spaces, and I’m enjoying the process of choosing what to keep, what is useful to my life now, and what can go. Keep the memories, not necessarily the stuff.

All in all, I’ve been very happy with the studio swap, as I have more space now, and better light during the day for weaving, spinning, and cranking socks. Evenings, I work upstairs, closing toes on socks, sewing, and combing/carding fleece. Last night I worked on some wonderfully lustrous Lincoln fleece, using a flicker as it is too long for the drum carder. There is always more to learn, and how to use wool combs is on my list.

“Holly & Ivy,” newly cranked, are shown below. Pat received her red and black “Checkerboard” socks in the mail, Carol is coming over Wednesday to choose four pairs of socks and in this bitter cold weather, I could use a few more pairs of wool socks myself. As I write this, it is -16 F., and dropping.

Socks Gone Astray

In October, a woman had purchased a pair of socks, “Goldenrod in Bloom.” She liked them so much she contacted me in October to order three more pairs, which I made up and mailed to her on Nov. 4th. I had a tracking number, but as I’ve never had a package not be delivered, I did not check up on it. Later in November, she emailed me and asked if I had sent the socks out as they had not arrived. I wrote back telling her when they were mailed, then got on the usps.com site to check tracking.

Usps said the socks had been accepted in Conover on Nov. 4, and processed on Nov. 5 at two different locations in IL. It did NOT say delivered. I checked with my local postmaster and she said found the same information. Back home, I dialed Information for a phone number at the IL post office in question. There, I was told they would get back to me within a business day. Late the following afternoon, I called them again and was told someone had called that morning and,… “Wait,” I said, “I just arrived home, I’ve been out all day, no one has been home, no message was left on my answering machine, so no one called here.” They did not know where the package was.

What could I do but go home and make three more pairs of socks and get them ready to mail, which I did. The day I took the second package to the post office, the postmaster asked me if I’d checked tracking that day. No, I hadn’t, so she did, and it appeared the package was in MN on its way back to me, so took the package back home again. It took about five weeks to make its way back to me.

The next day, the original package of socks was in my mailbox, mailing label missing, but a small label with return to Shuttle Works affixed to it, and the end taped shut.

I took photos of the outside, then opened it, and yes, it had been opened, the raffia nearly off, tissue re-wrapped, and in the bottom of the envelope one of my business cards/tags that had been inside a sock. I called Deb again, and she said the label must have come off at some point going through the machinery, and the package sent to recovery, where they are authorized to open packages to try to determine the destination or origin. They had found my card and were able to send it back.

So, the following day, back I went to the post office, this time clear tape over the label to make sure it would not come off, insured, tracking number, and signature required. I also sent a package to Oregon, another sock order. Both arrived at their destinations the same day. Then last night I received an email from OR that the socks had arrived. I wrote back thanking him for letting me know, and briefly telling him about the other package that had gone astray. He wrote back saying he had looked, and the label was coming off that package, too.

Live and learn, right? Either replace the labels or clear tape over each one to keep it on (or both), or just write directly on the packages with permanent marker.

And now I’m three pairs of socks ahead on my sock supply for the coming summer.

More Sock Orders

After being away for a few days for Thanksgiving, visiting my parents/family members, I returned home to finish up a sock order for Ann, who when she ordered them had said “no hurry.” Left to right, “Wild Blueberries,” “Cranberry Harvest,” and “Raven Trail.” Thank you, Ann!

After being away for a few days for Thanksgiving, visiting my parents/family members, I returned home to finish up a sock order for Ann, who when she ordered them had said “no hurry.” Left to right, “Wild Blueberries,” “Cranberry Harvest,” and “Raven Trail.” Thank you, Ann!

Along with Ann’s order, it was time to make another pair of socks for Pat, who had called to order a second pair of Checkerboard (red and black). Her phone message of, “I just LOVE my socks!” really made my day. Did I have the yarn to make another pair? Yes, so when Ann’s order was finished, another pair of “Checkerboard” came off the sock machine. Enjoy!

Then an email came. Could I make a pair of socks, for a gentleman’s wife, for Christmas. Yes! So “Keep Me Warm” were also made up. A couple nights ago I had a nice sock wash and they have been drying by the woodburning range in the kitchen. Today 8 pairs of socks were finished with some steam, tags written, and they will be taken to the post office shortly.

Meanwhile, I had ordered more anchor pins for my Glimakra loom treadles as I was FOUR short for tieing up the ten shafts/twelve treadles. I have some of Texsolv ties and anchor pins missing in action around here somewhere.

I also ordered a tube of seine twine so I can begin making additional long-eye “string” heddles for the drawloom. There are ten ground shafts on that loom, nine of them have approximately 100 heddles each, and one shaft currently has none, and that needs to be changed. Now, I need to try to make a heddle jig, or have one made. Moving along,…

Yesterday, I went back to work on sock orders. Above, is “Raven Trail,” the first of three pairs of socks for a potter friend. Another sock order came in by phone a couple days ago, from a woman saying, “I just LOVE my socks! I need another pair.”

Yesterday, I went back to work on sock orders. Above, is “Raven Trail,” the first of three pairs of socks for a potter friend. Another sock order came in by phone a couple days ago, from a woman saying, “I just LOVE my socks! I need another pair.”

Unfortunately, another order will need to be replaced as a post office in IL has apparently lost the package, and phone calls to them have not brought it to light. I did have a tracking number which ends with “processed,” and not “delivered.” The replacement pairs of socks will be sent by UPS or FedEx as I won’t trust that post office again. Looks like I’ll have to start insuring all these packages, too.

I also sent off photos and text (and directions) for the Northwoods Art Tour brochure and website for the 2009 tour, so that was a good job done. I do need to arrange a day/time to go pick up the banners I will need next summer.

I’m still working on the loom, in-between a number of other committments. Yesterday and today, for example, I’ve been hard at work compiling and editing a newsletter for the Double Harness Study Group (of Complex Weavers). As I write this, I am also printing the color pages on our inkjet printer, and later will put them together and package them up. I thought it would be nice to have them arrive right before or after Thanksgiving.

Today, taking a break from the computer, I tied the warp on, removed the locking pins on my CM loom and removed the shaft holders. Not too long ago, I did a lot of readjusting on the loom, and today it all looks good. However, treadles need work as there is not always a clear shed. I knew this was coming, so tomorrow, it’s back under the loom. I believe after this warp is done, I’ll leave the tie-up the same for a bit, but change colors, texture, and treadling order. For now, I just want to be finished with setting things up and be able to sit and weave.

Treadles & Heddles

This was another typical early winter day in the northwoods of WI, alternating frequently between snow and sunshine, with a skim of snow-covered ice across our small lake. Inside it was cozy warm, the woodburning range pouring out heat, cats sprawled out around the stove, enjoying the toasty warm pine floor.

A couple days ago the 120 Texsolv cords were put on the lamms. Last night, the treadles were tied up.

After several days of interruptions and shifting priorities, I am back working on the CM loom. Days ago, I had found quite a number of tie-up cords missing, so I ordered a spool of Texsolv cord. Today I counted out cords to see how many long and short cords I had, cut those needed and with a lit candle, slightly melted the ends to make it easier to pass them through the holes in the lamms. Since I’m setting up for a ten shaft twill plus plain weave, I needed 60 long cords and 60 short cords (shown above).

Sitting inside the loom, I added the long cords to the upper lamms and my 16 year old daughter , after being shown how, added the short cords to the lower lamms. Then after tieing up the treadles, I’ll be able to thread the heddles, tie the warp on, and begin weaving.

In addition to the bleached and unbleached cottolin for weft, I have cones of white slub cotton, and also found cones of unbleached slub tow linen on my shelves, so I will have even more variety in design choices. I am going to enjoy weaving these towels and table runners.

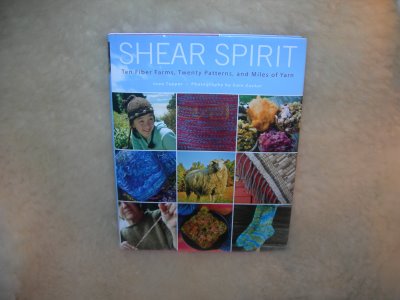

Weaving Library Additions

I’ve long been known to family and friends as a bookoholic, seemingly as necessary to me as oxygen, and this week was no exception. When not busy with looms, teens, and home, I’m found with book(s) in hand.